Health Risk Alert:

Diesel Particulate Matter (DPM) & Workplace Safety

Health Risk Alert:

Effects of Diesel Particulate Matter on Workplace Safety

Diesel engine emissions remain a serious occupational health hazard, particularly in mining, construction, and industrial sectors. A major component of these emissions is Diesel Particulate Matter (DPM), a fine mix of harmful particles that, if not properly controlled, can pose significant health risks to workers.

What is Diesel Particulate Matter (DPM)?

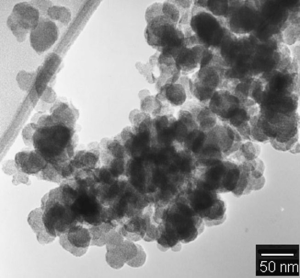

Diesel Particulate Matter is produced during the combustion of diesel fuel and is made up of microscopic particles, including:

- Carbon soot, the core of DPM emissions.

- Ash and metallic abrasion particles from engine wear.

- Sulfates and silicates from fuel and lubricant additives.

- Elemental and organic carbon compounds that bind toxic substances like PAHs (polycyclic aromatic hydrocarbons).

These particles are so small that they can penetrate deep into the lungs and bloodstream, making them extremely hazardous to human health.

The Health Risks of DPM Exposure

Long-Term Health Risks:

- Cardiopulmonary diseases

- Chronic respiratory conditions

- Lung cancer

- Increased risk of heart attacks and strokes

Short-Term Health Effects:

- Headaches

- Dizziness and nausea

- Eye, nose, and throat irritation

- Difficulty breathing, especially in poorly ventilated environments

How to Reduce Exposure to Diesel Particulate Matter

To effectively reduce DPM exposure in the workplace, a layered hierarchy of controls should be adopted. These include:

Engineering Controls

- Diesel Particulate Filters (DPFs): High-efficiency DPF systems can remove

up to 99% of particulate emissions. - Low-emission engines: Upgrade to cleaner, compliant engine technologies that emit fewer harmful byproducts.

- Preventive maintenance: Well-maintained diesel engines emit fewer particles.

- Improved ventilation: Essential in underground or enclosed areas

to disperse accumulated DPM. - Filtered operator cabs: Protect machinery operators by filtering the air they breathe.

Administrative Controls

- Limit engine idling: Reducing idle time directly lowers emissions.

- Training & awareness: Educate workers on DPM risks and safe work practices.

- PPE (Personal Protective Equipment): Use certified respirators in high-risk zones where engineering controls are insufficient.

How HJS SA Can Help

At HJS Emission Technology SA, we are dedicated to improving air quality at the source. We specialize in advanced emissions control solutions, including:

- Diesel Particulate Filters (DPF)

- Diesel Oxidation Catalysts (DOC)

- Custom emission systems are designed to meet stringent mining and industrial requirements.

Our goal is to help businesses protect their workforce, meet environmental compliance, and operate efficiently, without compromise.

👉 Contact us today to find out how we can support your DPM management strategy.

**This article is based on guidance from the U.S. Department of Labour’s Health Alert on Diesel Particulate Matter, April 2024.**