SCRT + TM

AFTERTREATMENT SYSTEM

SCRT + TM

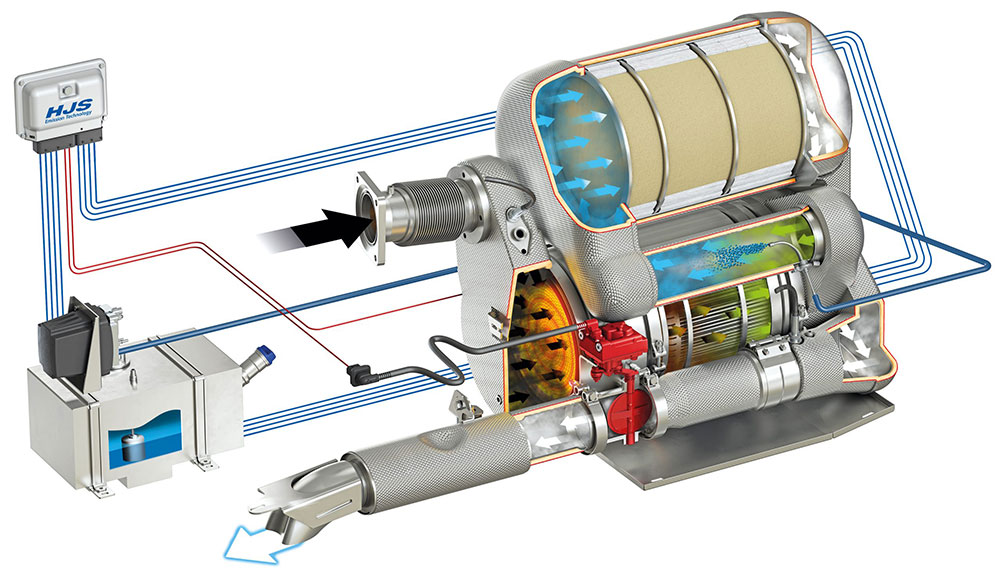

Highly efficient aftertreatment system with active thermal management strategies

Many commercial vehicle applications, mobile machines, and stationary applications have load profiles that, owing to the low exhaust-gas temperatures, necessitate the use of active thermal management in order to guarantee full functional reliability of the exhaust aftertreatment system.

This is important for regeneration of the particulate filter and the DeNOx system, which need a certain temperature for proper functionality, especially in light of Euro VI or Stage V emission standards and their emission requirements over their lifetime.

Established methods include burner-based systems, systems for hydrocarbon (HC, i.e., fuel) dosing downstream of the engine, downstream HC conversion in a catalytic converter, or a combination of the latter two. However, the high requirements of today’s and future emission standards can only be partially met by engine-based thermal management.

HJS adapts this concept as a self-sufficient system architecture to exhaust aftertreatment. The HJS exhaust gas system with active thermal management (SCRT®TM) uses two interlinked actuators to ensure that the system can be operated even with low loads under all environmental conditions. This ensures the best possible reduction performance without influencing the engine.

Our latest technical approach also includes an electrically heated oxidation catalyst. Maximum efficiency and robustness – HJS systems make sure that even the most stringent emission standards cause no risk of non-compliance or machine downtime!

Advantages

1. Ensures Compliance with Emission Standards

Maintains optimal exhaust temperatures for reliable DPF regeneration and DeNOx (SCR) system performance, even under low-load conditions.

Prevents non-compliance risks by ensuring emission targets are met over the entire system lifetime.

2. Active Thermal Management for Low-Temperature Applications

Solves the challenge of low exhaust-gas temperatures in commercial vehicles, mobile machinery, and stationary engines.

Uses two interlinked actuators to actively control heat, enabling efficient aftertreatment without engine modifications.

3. Self-Sufficient & Engine-Independent System

Unlike engine-based thermal management (which has limitations), HJS’s standalone system ensures consistent performance regardless of engine load or ambient conditions.

Reduces dependency on engine recalibration or fuel dosing strategies.

4. Advanced Heating Technology for Maximum Efficiency

Features an electrically heated oxidation catalyst (eHOC) for faster light-off and improved cold-start performance.

Enhances HC (hydrocarbon) conversion and particulate filter regeneration efficiency.

5. Robust & Reliable Operation

Designed for harsh conditions, ensuring durability in construction equipment, trucks, and industrial applications.

Minimizes machine downtime by preventing failed regenerations or aftertreatment faults.

6. Future-Proof Solution

Adaptable to even stricter future regulations.

Combines burner-based systems, HC dosing, and catalytic conversion for maximum flexibility.